Case Studies

Lean: Invoicing Process

Problem

An Engineering Design Firm requested assistance in evaluating their Client Invoicing process. The process for was very inefficient, due to numerous redundant steps, bottlenecks and far too many handoffs. These inefficiencies resulted in rework, delays and frustration for both employees and clients.

Solution

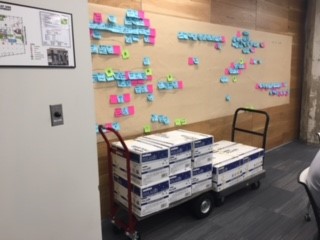

Several process improvements were implemented based on a 4-day Value Stream Analysis ProcessSM, which documented the current state, designed the future state, and developed a project plan to implement and track the improvements. OPS provided on-site implementation support and helped manage the execution of the plan, providing regular progress reviews with the Design Firm.

Results (First six months of implementation)

- Lead time of the process was reduced by 55%, allowing the organization to effectively maintain cash flow even during remote operations caused by the coronavirus pandemic

- Productivity was doubled by reducing lead time without investing any capital or hiring additional staff

- Project savings from the reduction of lead time are currently estimated at greater than $1M with only one division implemented

- Benefit to cost ratio of greater than 20 to 1

- Internal customer comments: "Invoicing is no longer a burden, our pre-close meetings are collaborative, and similar dialogues between our project managers and project accountants have reduced touches and rework! I highly recommend embracing this process whole-heartedly!"

Case Studies

- Lean Leadership

- Lean Government: Workforce Center

- Lean Government: Science Center

- Lean Healthcare: Emergency Department

- Lean Healthcare: Sterile Processing Department

- Lean Healthcare: Nursing Unit

- Lean Healthcare: Utilization Review

- Lean Manufacturing: Auto

- Lean Manufacturing: Armor

- Lean Training

- Lean Invoicing Process

410-871-0995